200*1000 Electro-Permanent Magnetic plate

| Price: |

1230.0 USD |

| Payment Terms: |

T/T |

| Place of Origin: |

Zhejiang, China (Mainland) |

Product Detail

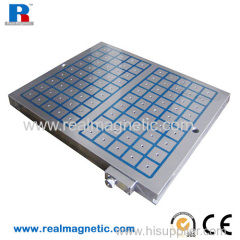

Model No.:

EPM75H-210

Production Capacity:

100sets/month

Delivery Date:

about 25 days

Processing:

Milling Machine

Workpiece and Weight:

Instrument Machine Tool

Controlling Mode:

CNC

Brand Name:

Realmagnetic

Function:

Fix object

Export Area:

global

Means of Transport:

Ocean,Land,Air

Packing:

plywood

Processing Types:

Metal

Automatic Grade:

Automatic

Precision:

High Precision

Usage:

General

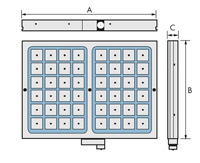

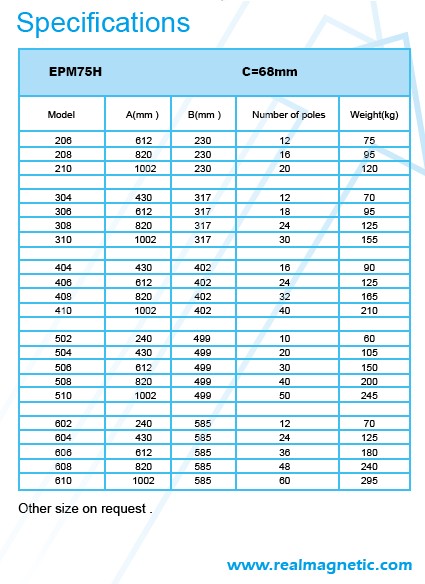

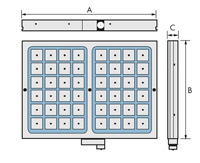

Specification:

As your requests

pole:

75*75 mm

pole number:

20 pcs

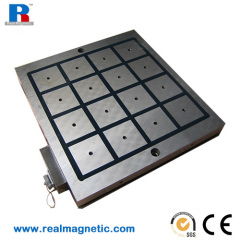

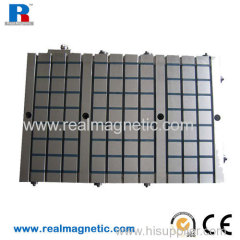

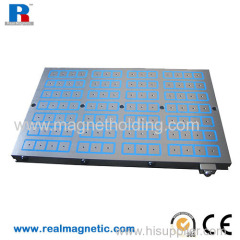

larger pole electro permanent magnetic chuck

High-density polar version comprising size 75 poles with a force of 780 kgf for each pole.

Flexibility

5sides clear machining access

All useful strokes used

Work pieces larger than the table surface are machinable

Unique tooling

Simplified CNC or FMS programming | Cost-effectiveness

Limited capital outlay

No maintenance

No modification to the machine and to the line

Energy-saving

Reduced consumption of tools

High-value over time | Safety

Constant and concentrated force

No electric power supply during clamping

Ergonomic in operation

No dispersion of magnetic flux

No interference | Productivity

Easy and quick set-up

Drastic reduction in downtime

Higher stock-removal rates

Facilitated interaction with CAD/CAM systems

Improved finishing and greater accuracies |

|

Selecting the right solution |

The standard series of Super-EPM chucks include more versions which have different performance characteristics. Capable of adapting to different operating needs, depending on the thickness. The surface condition (or the operating air gap) and the dimensions of the work piece to be clamped. The clamping force of each version depends on the different dimension types of poles and on the configurations of the magnetic area.

Each pair of N/S poles generates an autonomous and defined force which is not influenced by the operating conditions of the other adjacent poles. Therefore by counting the number of poles occupied by the clamped piece it is possible to predetermine the force generated and consequently to establish the usable machine power with the relative machining parameters.

As an indication we can say that a pair of size 50 poles (50*50mm) can enable processing of up to 2 kw machine absorption, while a pair of size 75 poles (75*75mm) can go up to 4 kw |

High-density polar version comprising size 75 poles with a force of 780 kgf for each pole.

Particularly suited for use with fixed and mobile polar extensions and ideal for pieces of every size with normal operating air gaps and medium thicknesses. |

Flexibility

5sides clear machining access

All useful strokes used

Work pieces larger than the table surface are machinable

Unique tooling

Simplified CNC or FMS programming | Cost-effectiveness

Limited capital outlay

No maintenance

No modification to the machine and to the line

Energy-saving

Reduced consumption of tools

High-value over time | Safety

Constant and concentrated force

No electric power supply during clamping

Ergonomic in operation

No dispersion of magnetic flux

No interference | Productivity

Easy and quick set-up

Drastic reduction in downtime

Higher stock-removal rates

Facilitated interaction with CAD/CAM systems

Improved finishing and greater accuracies |

|

Selecting the right solution |

The standard series of Super-EPM chucks include more versions which have different performance characteristics. Capable of adapting to different operating needs, depending on the thickness. The surface condition (or the operating air gap) and the dimensions of the work piece to be clamped. The clamping force of each version depends on the different dimension types of poles and on the configurations of the magnetic area.

Each pair of N/S poles generates an autonomous and defined force which is not influenced by the operating conditions of the other adjacent poles. Therefore by counting the number of poles occupied by the clamped piece it is possible to predetermine the force generated and consequently to establish the usable machine power with the relative machining parameters.

As an indication we can say that a pair of size 50 poles (50*50mm) can enable processing of up to 2 kw machine absorption, while a pair of size 75 poles (75*75mm) can go up to 4 kw |

High-density polar version comprising size 75 poles with a force of 780 kgf for each pole.

Particularly suited for use with fixed and mobile polar extensions and ideal for pieces of every size with normal operating air gaps and medium thicknesses. |

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Find more related products in following catalogs on Hisupplier.com